At present, China has the most complete industrial system in the world. Moreover, it has been making new technological breakthroughs in high-end manufacturing fields such as aerospace, shipbuilding, new energy, and semiconductor manufacturing.

At present, China has the most complete industrial system in the world. Moreover, it has been making new technological breakthroughs in high-end manufacturing fields such as aerospace, shipbuilding, new energy, and semiconductor manufacturing. The development fundamentally depends on the basic materials research. The way of material research has also extended from the initial method of process formula plus experiments to more studies on process change characteristics.

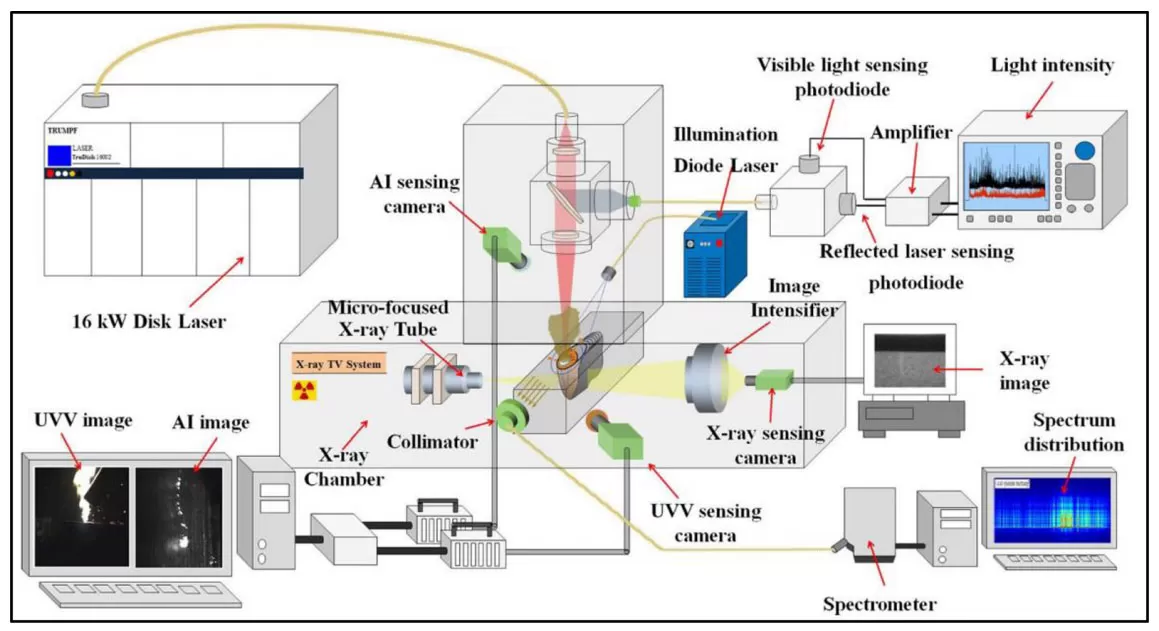

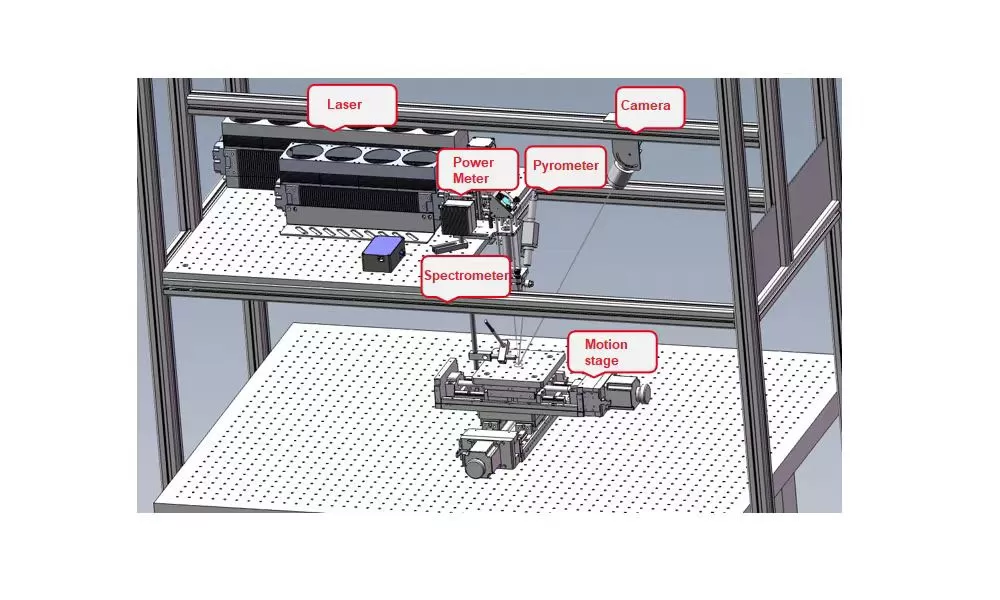

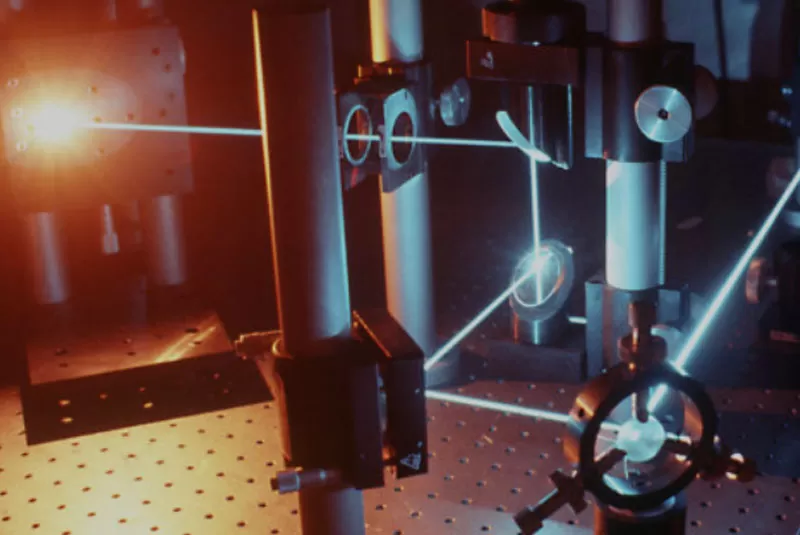

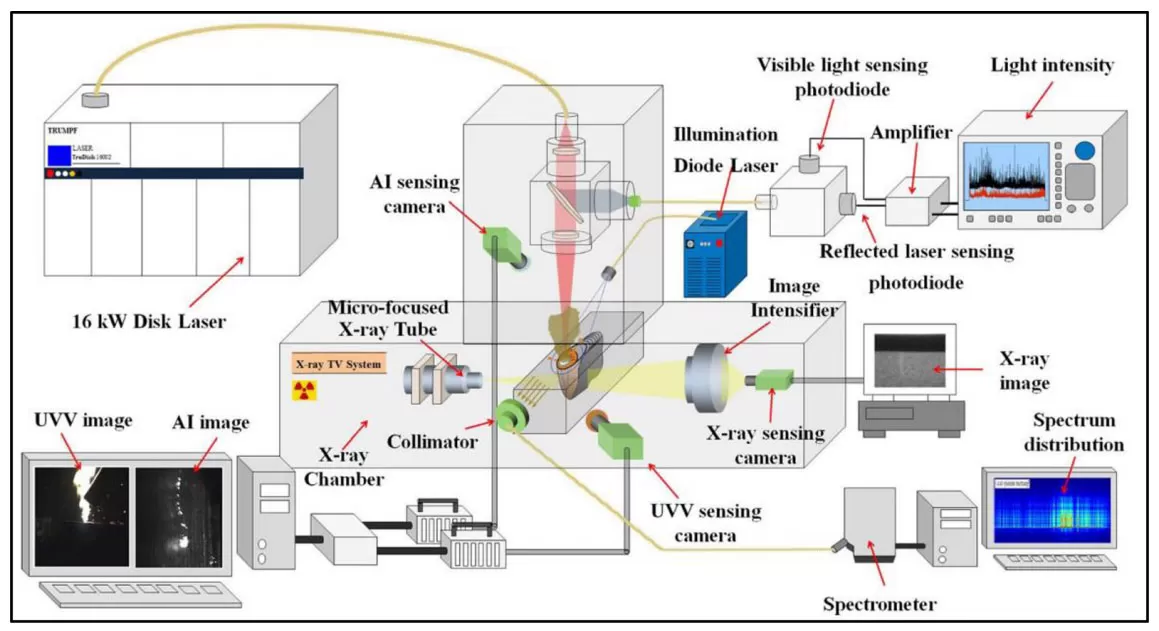

The relationship between irradiation energy and materials has always been a key research focus. In line with the latest technological development trends, heating/irradiating materials with high-power lasers and synchronously collecting process data of the materials using various sensing instruments for analysis, and then optimizing and adjusting the material process, has become a highly favored approach among researchers.

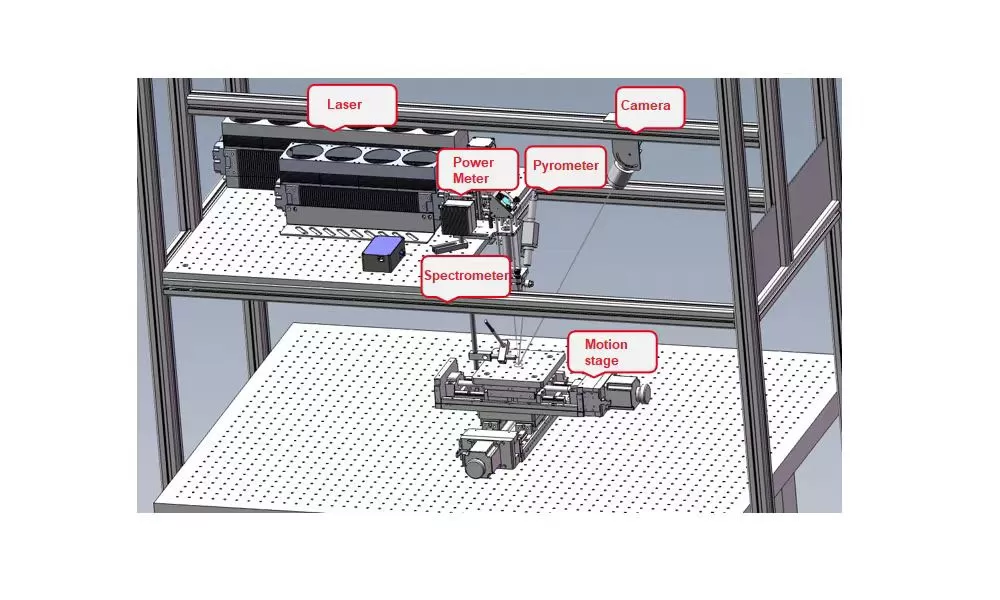

Multi-sensor system based on laser heating

Brolight rich industry experience and solid technical foundation enable it to provide customized solutions for this type of material application research. The solutions offer a complete set of systems, including configurable hardware and software functional modules, and achieve data interaction and correlation between hardware sensors through software, providing rich data support for research work. As shown in the following figure, the system can cover extremely broad application research, such as heating of special metal materials, auxiliary heating of alumina materials, and parameter measurement during the irradiation process of photonic materials, etc.

Schematic Diagram of Customized Complete Machine System