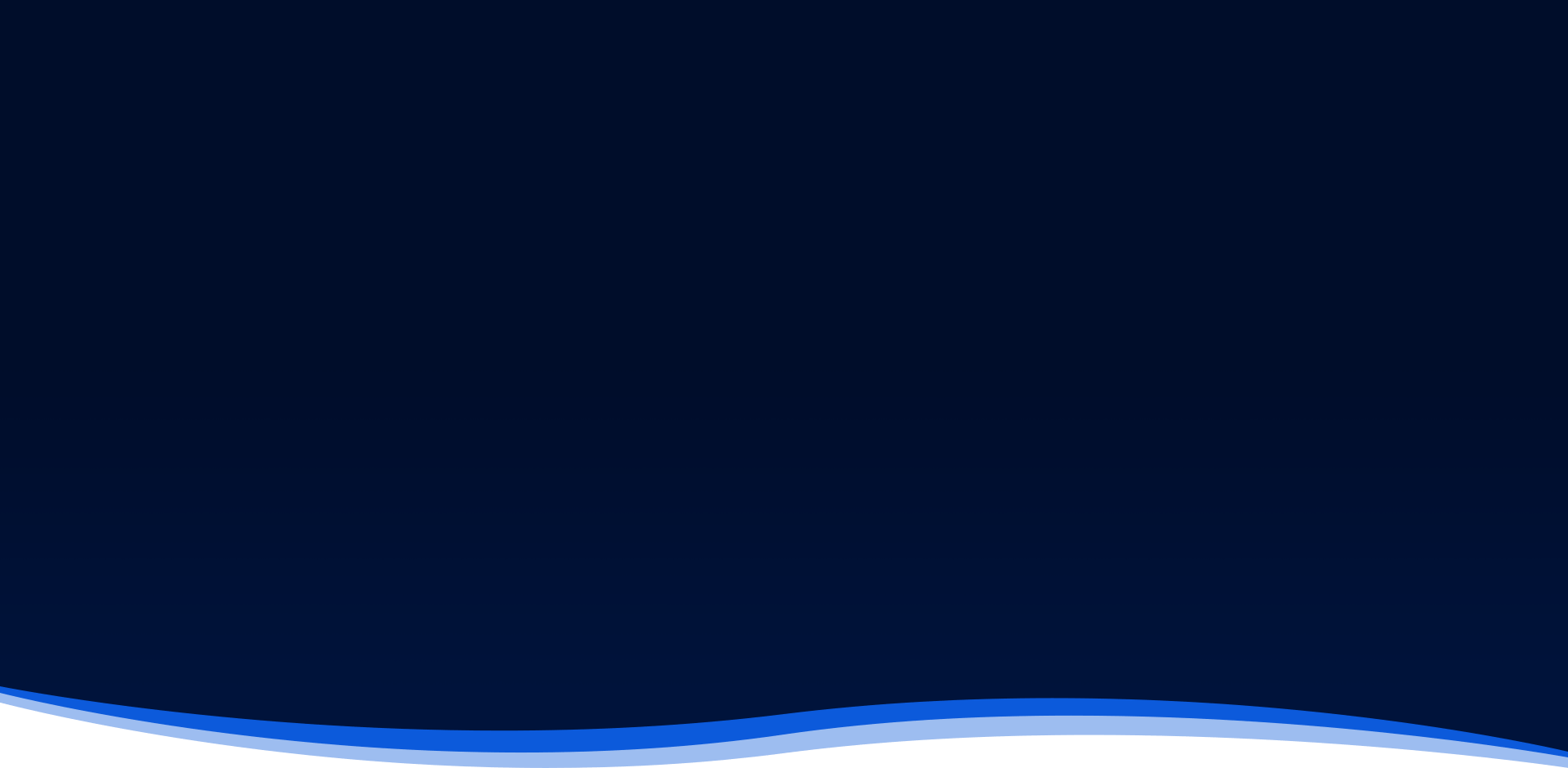

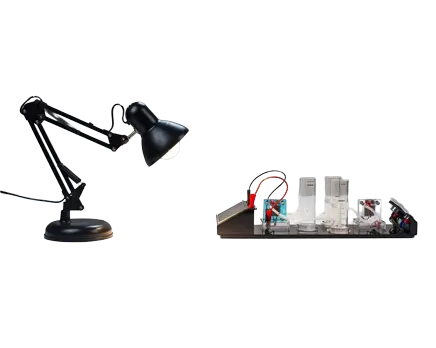

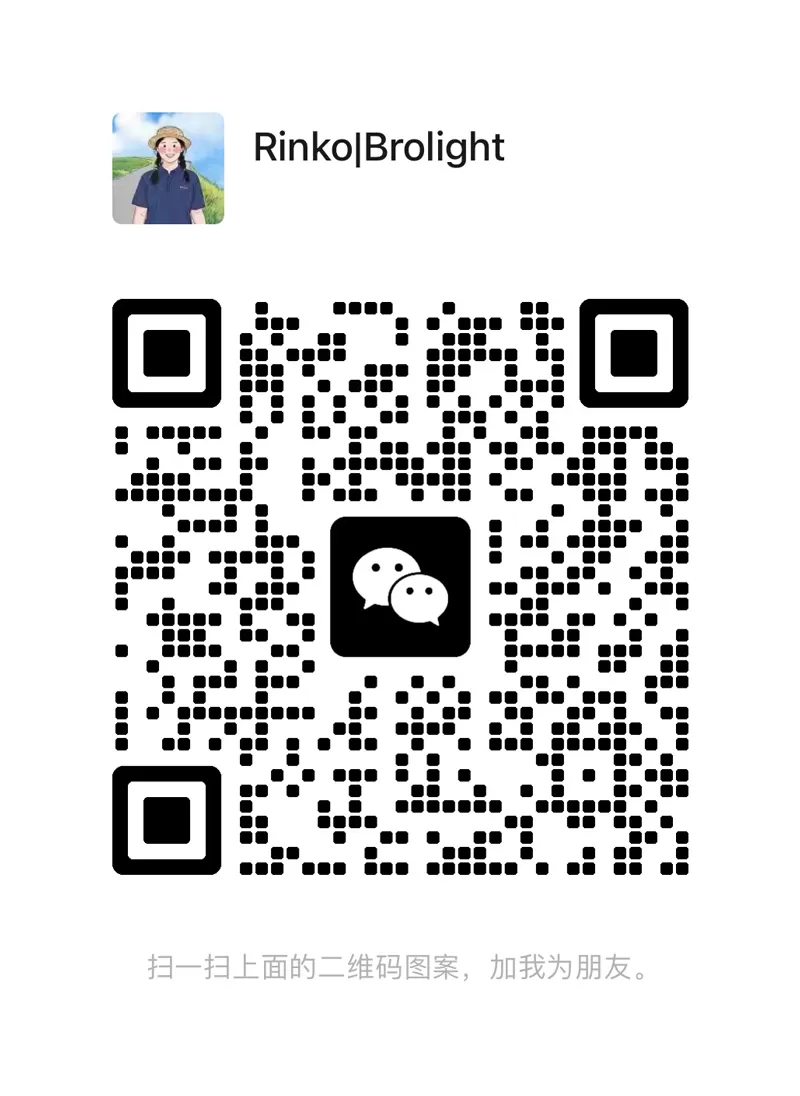

1. Electrical & electro-optical conversion experiment

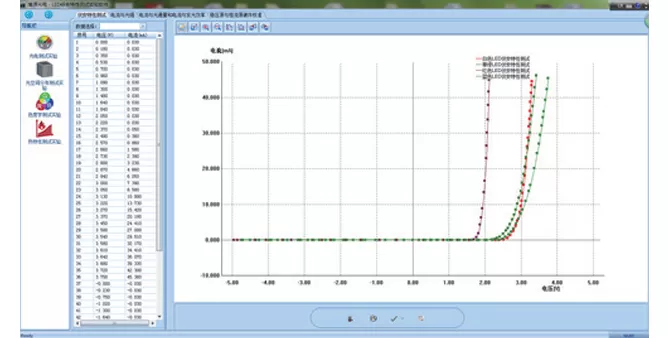

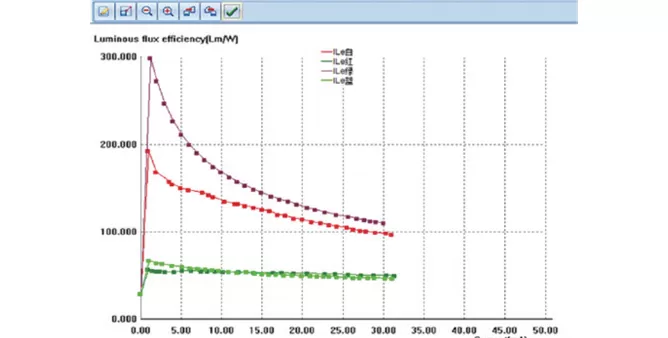

2. Investigate the relationship between current, luminous flux and luminous efficiency

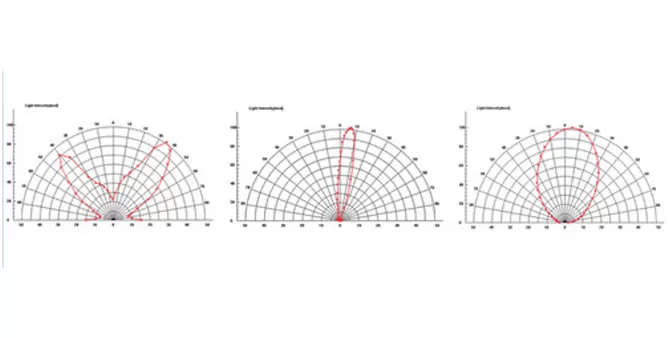

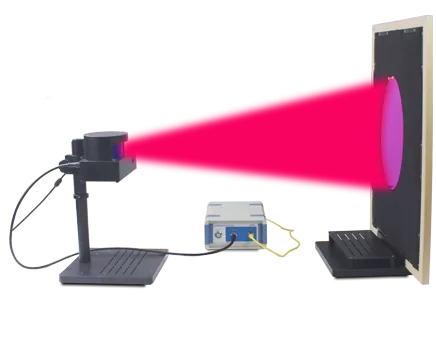

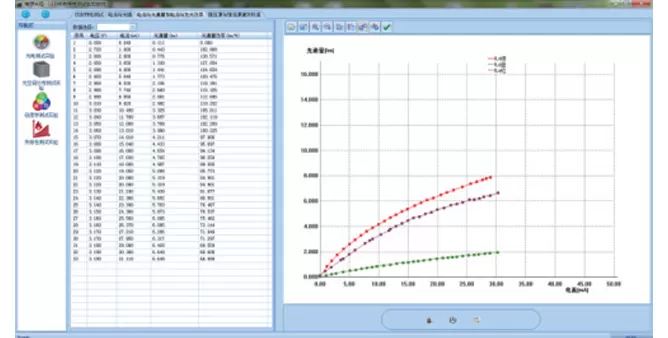

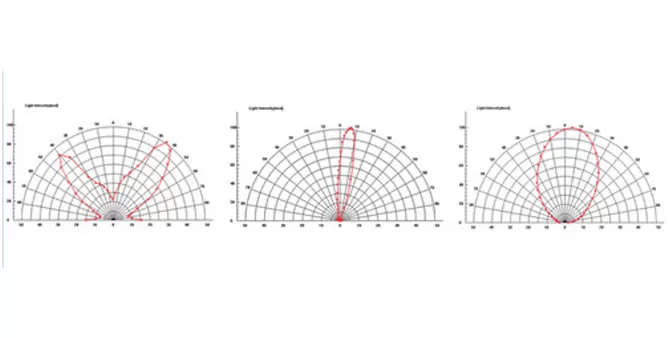

3. Light spatial distribution (light distribution curve) experiment

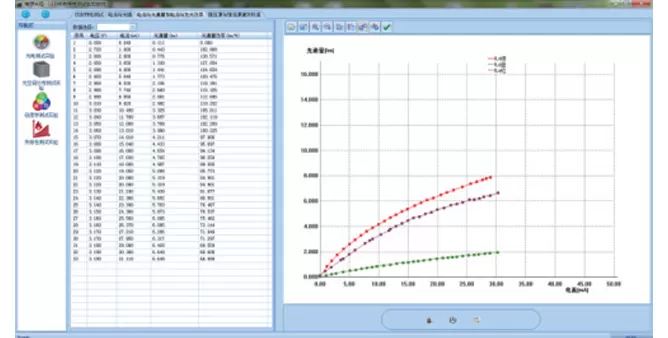

The curve showing the variation of the average

light intensity in one-dimensional space with the current

Two-dimensional spatial light distribution

(light distribution) curve

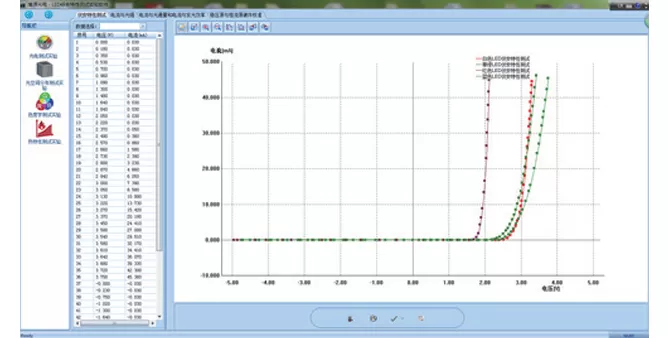

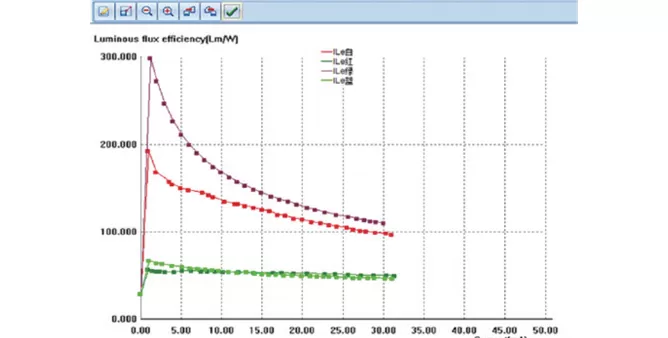

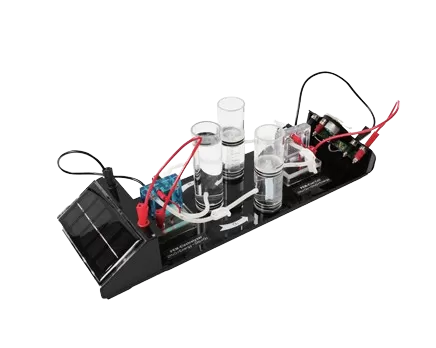

4. The curve showing the relationship between current and luminous flux

The curve showing the relationship between current and luminous efficiency

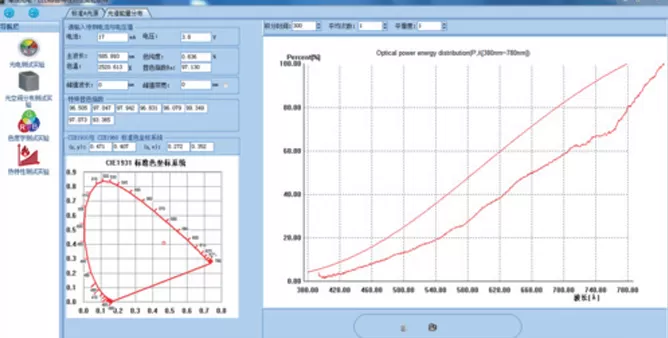

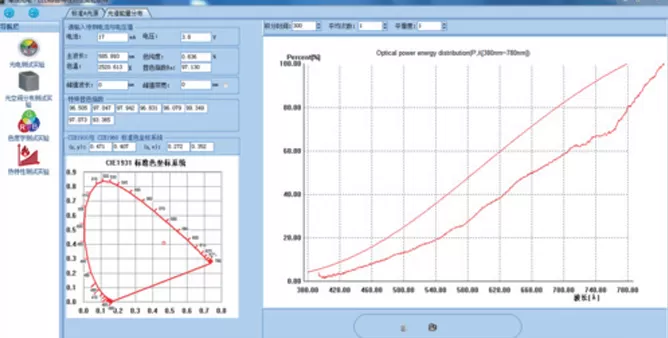

5.Measure the chromaticity parameters of different LEDs

The curve showing the relationship between current and luminous efficiency

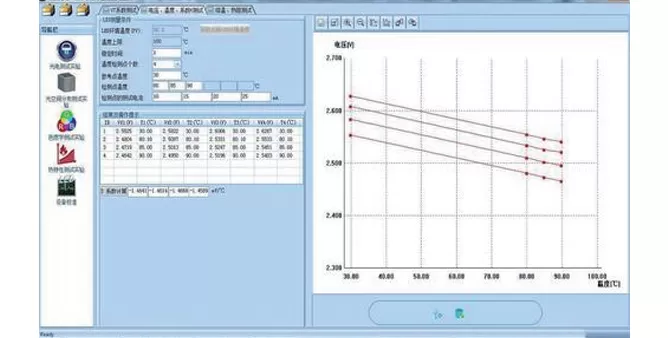

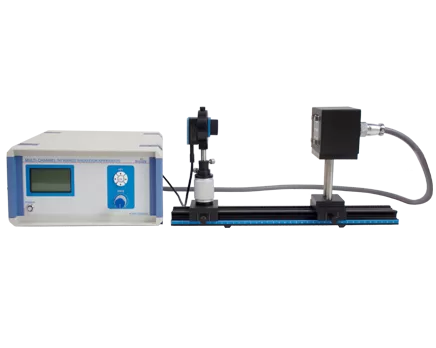

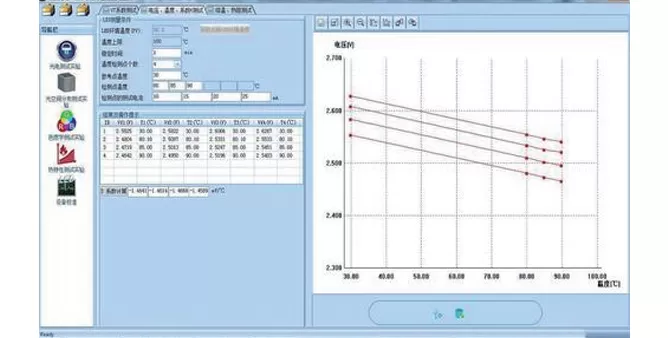

6. Thermal Characteristic Test Experiment

This module is used to measure and calculate the K coefficient, thermal resistance, and junction temperature of LEDs. The experimental setup includes a temperature control system, a temperature control power supply, and a pulse power supply. After the experiment begins, the voltage-time curve can be displayed in real time on the software interface, allowing for the analysis of the junction temperature and thermal resistance at the steady state.

Small current K coefficient test