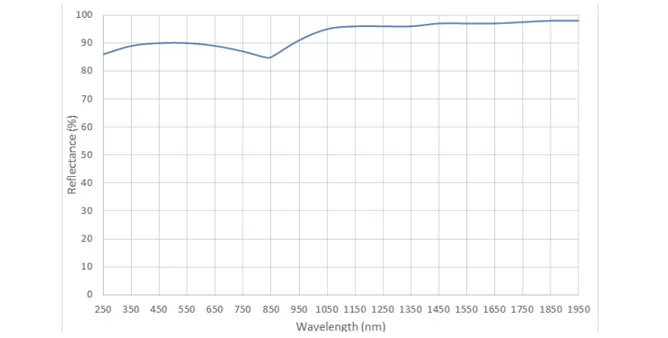

This Mirror Reflectance Standard can be used when setting a high reflectance reference. The surface of the standard is protected by a layer of fused silica coating, and care must be taken to ensure that the surface of the standard is not damaged. Do not touch the surface with your hands or objects to avoid contamination and damage. When cleaning the surface, it is recommended to blow off the dirt and dust from the surface with high pressure gas, and then remove fingerprints and fixed residues from the surface with the traction cleaning method. Traction cleaning method is to use the lens paper with acetone or alcohol slowly pulled across the surface of the lens. Then drag it unidirectionally on the mirror surface, and let it dry naturally afterwards. Usually does not require wiping. After the solvent evaporates evenly, it will not leave any tailing or stains on the surface of the lens.